Ultrasonic Vibrating screen

Parameter

Item | Ultrasonic vibrating screen |

Model | S49-B |

Layer | 1-5 |

Diameter | 400mm-2600mm |

Sieve area | 380mm-2550mm |

Aperture hole size | 0mm-10mm |

Mesh size | 0mesh-700mesh |

Application | Powder,granula,liquid |

Max feeding size | Below 30mm |

Capacity | Depends on the density of material |

Material | SUS304,SUS316,Q235,etc |

Motor | Heat-proof(IP55) |

Rating of motor | 5-4,10-4,16-4,25-4,40-4,50-4,70-4 |

Exciting force | 2.5KN-75KN |

Rotate speed | 1450 r/min |

Power | 0.25KW-3.7KW |

Amplitude | 3mm-5mm |

Anti-blinding syestem | Ultrasonic generator |

Voltage(V)&Frequency(Hz) | Customized |

Noise | Below 50db |

Place of orgin | Henan(China mainland) |

Warranty | 12 months |

After sale service | Life time |

Dimension (Package) | Variable |

Weight(Package) | Variable |

Brief Introduction --- ultrasonic vibrating screen

Ultrasonic vibrating sieve

Ultrasonic vibrating sieve is standard vibrating sieve machine added an extra ultrasonic equipment on it.

The ultrasonic wave added on the sieve mesh makes the vibrating sieve able to screen/sieve fine powder/micro powder efficiently and precisely. The giant ultrasonic acceleration restrains blockage factors which includes adhesion, friction, wedging etc and improves sieving and cleaning efficiency.

It is able to improve the pancake and slip-effect of low-density powder in the gravity settling (light touch between powder and mesh), improving the occluding and wedging of high-density metal on the mesh, improving the adhesion effect of powder with the electrostatic, which improves the sieving efficiency and quality.

Calculating by sieving completion percentage, ultrasonic vibrating screen generally is able to complete sieving process 50%-400% more than one which is not ultrasonic device.

Application ---- ultrasonic vibrating screen Ultrasonic vibrating screen

Ultrasonic vibrating sieve machine has prominent advantages in solving materials sieving problems such as high absorption, easy agglomeration, high static, high precision degree, light weight etc.

Applicable materials includes metallurgy powder, electromagnetic materials, metal powder, welding rod powder, iron powder, zinc, aluminum powder, alloy powder, cobalt powder, molybdenum powder, emery,copper powder, nickel powder, silicon, oxidize titanium, tungsten powder, titanium powder, stainless steel powder etc.

Features ---- ultrasonic vibrating screen

(1) Less or no net-cleaning time.

(2) No assistant objects bring pollution to the powder body e.g. rubber ball.

(3) Keep the size of mesh precise and make the sieving precision stable.

(4) Disassemble the adhesion objects and reduce left material on the mesh.

(5) High screening efficiency.

(6) Processing material size 0~600 mesh.

Machine Structure -----ultrasonic vibrating screen

Machine Picture

Component and Parts(Ultrasonic generator and transducer)

How it works

----high efficiency and large capacity with ultrasonic cleaning system

----Best choice for super fine powder

Top Quality Motors-- Ultrasonic Vibrating screen

-----more durable

-----high exciting force

-----low power consumption

Accessories ---- Ultrasonic Vibrating screen

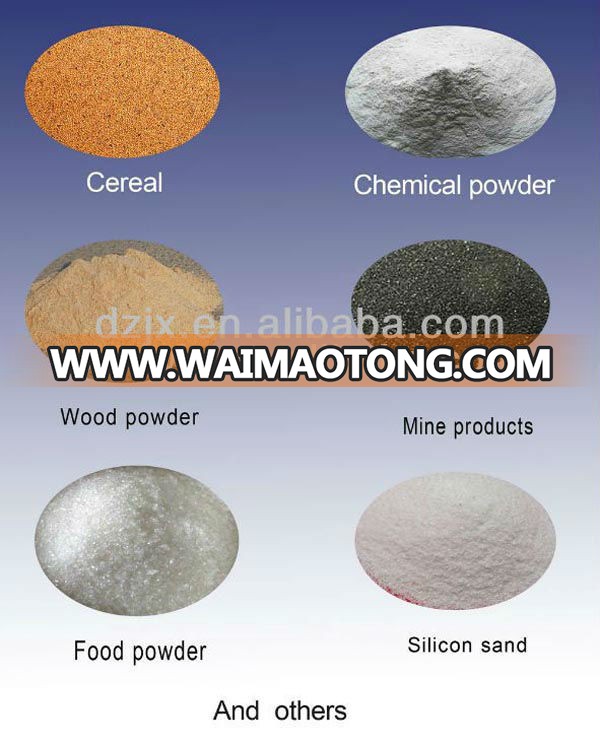

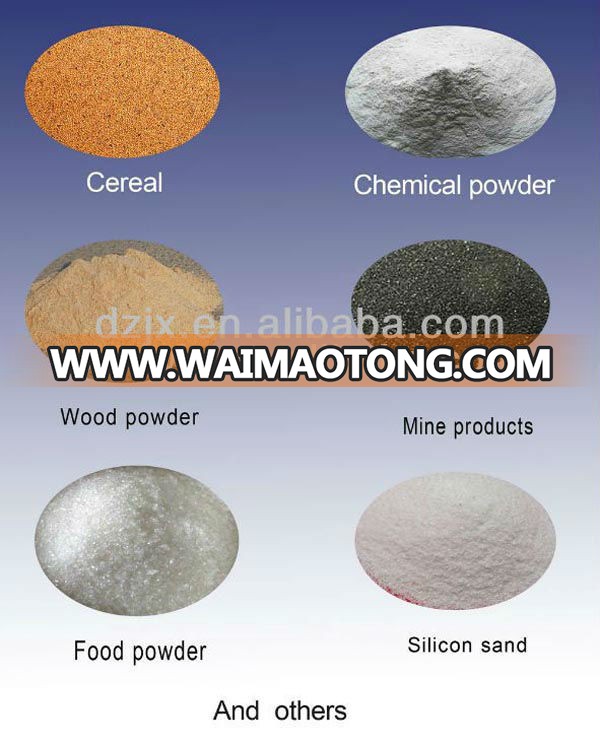

Applicable Materials ---- Ultrasonic Vibrating screen

----wide range application

----espcially for granule and powder

-----good solution for super fine powder(0-600mesh)

Packing and Shipment ------ Ultrasonic Vibrating screen

----enlaced with Wrapping film before packaged

----plywood package which is fumigation free

----please contact us for more packing information for your logistic computation

Application solutions:

Application 1:----- Ultrasonic Vibrating screen

Manufacturers of powdered detergents need to eliminate oversize granules, which detract from eye appeal of the product and retard the rate at which they will dissolve. Since the detergent is bone dry at time of scalping, dust and screen capacity are a problem with other types of sieving devices. Chenwei vibrating screen can handle the capacities that detergent manufactures require, while holding oversize material to a manageable level. The use of metal covers and flexible spout connectors also eliminate the dust.

Application2:---- Ultrasonic Vibrating screen

The production of high-quality citrus juice requires the separation of the pulp, seeds and rag (peel membrane) from the juice itself. Juice enters the top screen and flows through to the bottom. The top screen separates out the larger seeds and portions of rag; the second screen separates the desirable large juice sacs and passes the small embryo seeds and undesirable fine pulp; these latter are caught by the third fine mesh screen. The Chenwei vibrating screen are able to provide a higher quality juice by eliminating various stages of the process which necessitated pressure and maceration of the pulp.

Application 3:---- Ultrasonic Vibrating screen

Manufacturers of wall plaster from mortar cement for use in the construction industry start the process by extracting a certain particle size range from limestone. In a typical process, a crusher reduces raw limestone to granules. The material is then fed to one or more CHENWEI Gyratory Sifters for classification of the limestone. Most producers in this industry will utilize a unit over standard round or rectangular separators due to the capacity requirements and the gentle sifting motion produced by the unit.

Application 4:---- Ultrasonic Vibrating screen

In the processing of drug powders, pharmaceutical companies have difficulty with stamping tablets due to the fines present in tablet granulations. CHENWEI was able to eliminate this problem, while improving the quality of the product, increasing production rate and cutting costs. A round separator now removes all fines from granular material, resulting in a more uniform and better appearing tablet. There are also fewer product rejects. CHENWEI Separators have been so successful in the dry screening that the machines are now used for screening liquid pharmaceuticals to remove undissolved particles of medicaments.

For more separation and size reduction solutions,cotact us free!!!!

No matter How complicated it is.

No matter where you are located.

Company Information

Xinxiang Chenwei Machinery Co., Ltd is a manufacturer of vibrating screens, centrifugal sifters, tumbler screens, Ultrasonic vibrating screes,gyratory screens and aluminum foil tape with well-equipped testing equipment and strong technical force.

With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in mining, pharmacy, food, chemical, metal powder and other industries

About Us

Related Products

Maybe you will also have interest in our other products :

screening machine:

1.Rotrary vibrating screen

2.Trommel screen

3.Tumbler screen/sieve

4.Centrifugal sieve/sifter

5.Linear vibrating screen

conveying machine:

1. Horizontal screw conveyor

2.Inclined screw conveyor

3.spiral elevator

4.Bin Activator

FAQ:

Q:What factors I need to get a quotation?

A: Material bulk density, mesh size(length & angle for conveying series) & ideal capacity for proper type, granularity distribution is recommended. product material requirement (carbon steel Q235A, stainless steel SUS304 or SUS316,etc.) Voltage & Frequency(Hz) is also needed for a precise quotation.

Q:What is the real delivery time of your factory?

A: 7 to 15 days for general series products, meanwhile, batches products & customized products would need 30 days to 60 days based on different situations.

Q: How do you ensure the quality of your products?

A: Generally, our equipments are the most durable type in the industry, this is also the feature of the label impression of DZJX for most of our customers at home or abroad. With our experienced quality control team, we are trying to offer most of our customers the product with bset quality. However, we do recognized that there do have small amount of the product which may got faulty or damaged for different reasons.

Q: How do your after-sale service work if the product got damaged?

A: In the gurantee time 12 months, our general after-sale service is changing the damaged parts for the customer, but if the damage could be repaired by slight cost, we would wait for the customer's bill for the fix cost and refound this part of cost.(note: Vulnerable parts do not include.)

Q: How could I trust your promise?

A: Firstly, you may check the assessment on our website certified by the appraisal agency Bureau Veritas;

secondly, we attend at least 4 to 6 international industry exhibitions held in China annually, like the Food Ingredients China, China International Battery Fair, CPhI, ICSE BioPh China, ICIF China, etc. We usually met our customers there for negotiation;

Thirdly, company inspection always available, if you have any representative or you would like to come to our site, we offer free shuttle from Zhengzhou airport to our company, welcome your visit.

Please feel free to contact if you have any questions!

Our Services

Guarrantee and after sale service :

One year guarantee for the whole machine

24hours technical support by email

24 hours online service

Instruction in English language

User manual in PDF and Printed copy

Installation videos

Six free services including regular follow up services:

1.FREE technical enquiries

2.FREE repairs during warranty

3.FREE special services for key projects

4.FREE inspection upon delivery

5.FREE operation and repair training

6.FREE period follow-up and maintenance service